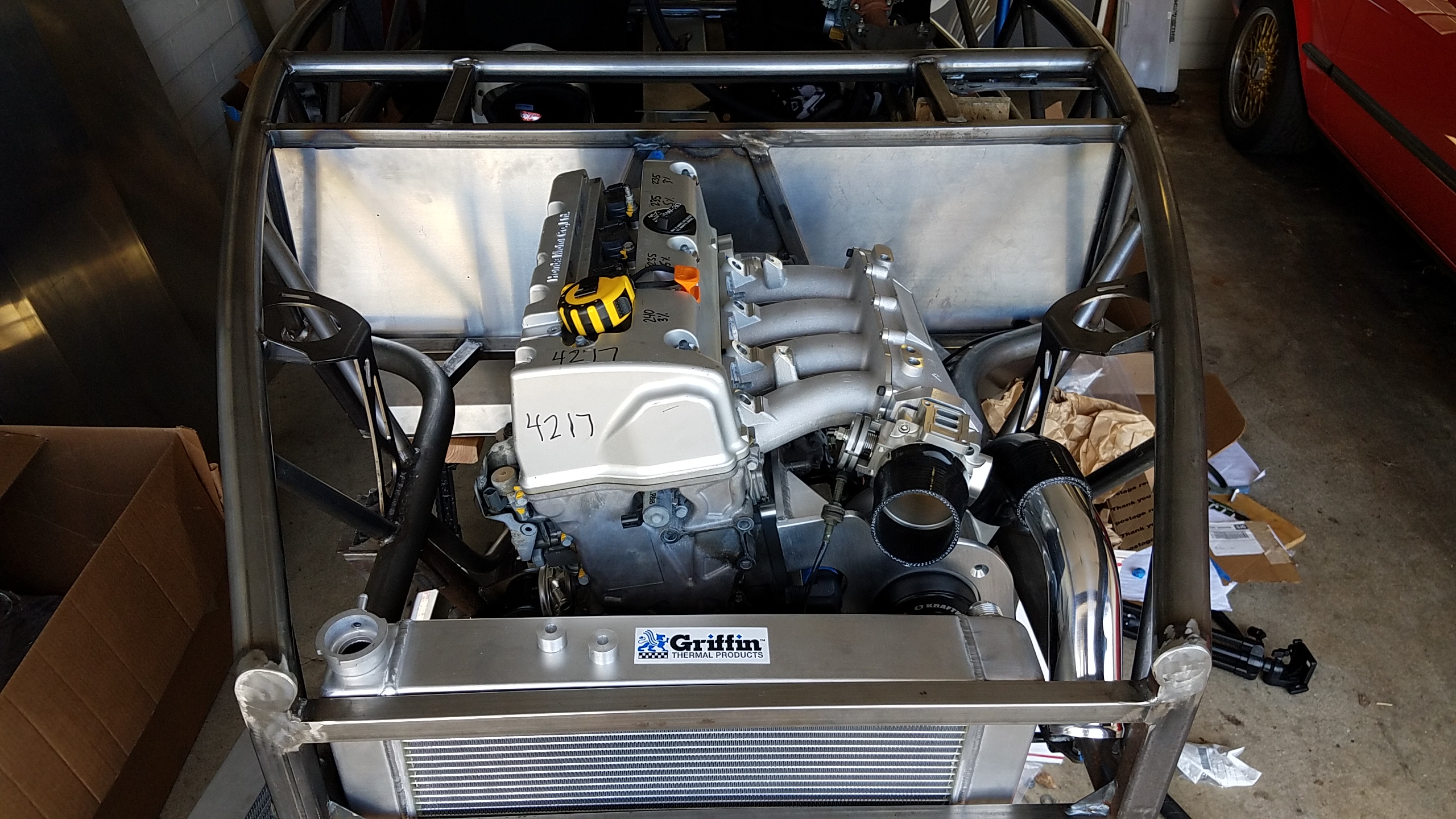

If you are new to the build, it’s an Exocet that will be powered by a high revving supercharged 4 cylinder with around 500hp. The final curb weight will be around 1700lbs! Check out our other posts as well and follow our facebook page to be kept up to date. Now on to the post…

Oil and Water Cooling

One of the biggest factors in engine longevity and reliability is proper cooling. Water usually warms up first, with the oil taking considerably longer to come up to temperature. Many people use water temperature as a guideline for when it is ok to drive the car hard, but usually an engine isn’t ready at this point because the oil is still cool. In addition to providing better lubrication once it is up to temperature, oil needs to reach over 200 degrees to evaporate any fuel and moisture that get in to the crankcase from blowby or crankcase ventilation. But if the oil gets too hot, it breaks down and its lubrication properties are diminished.

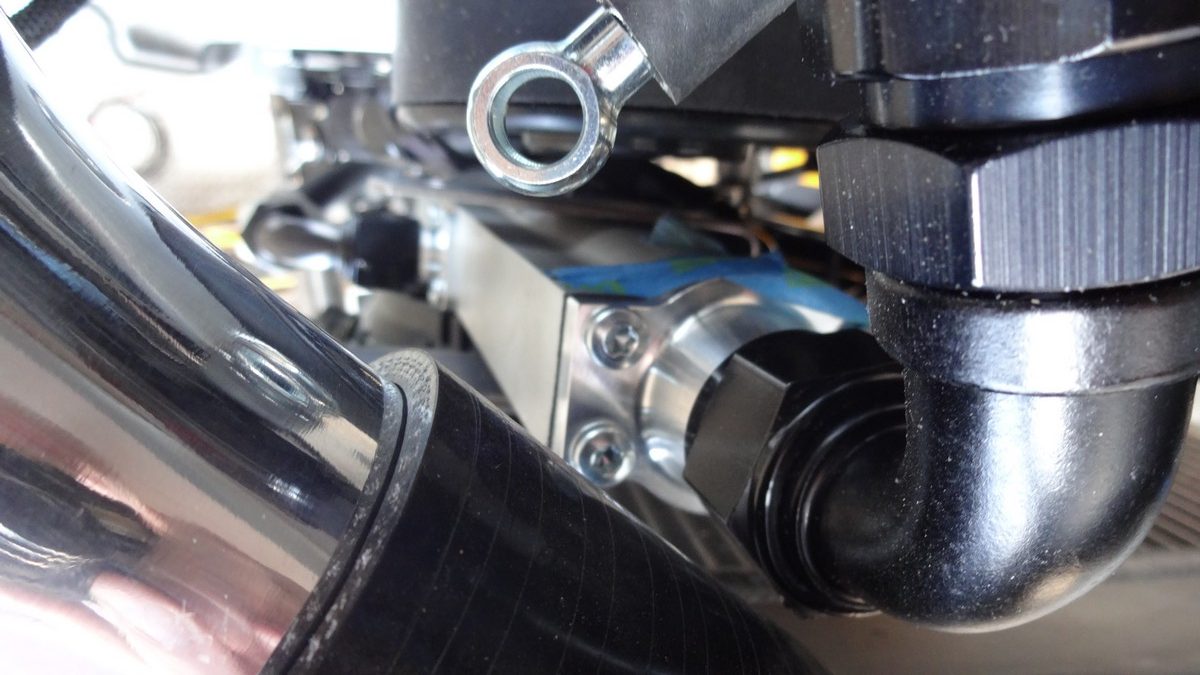

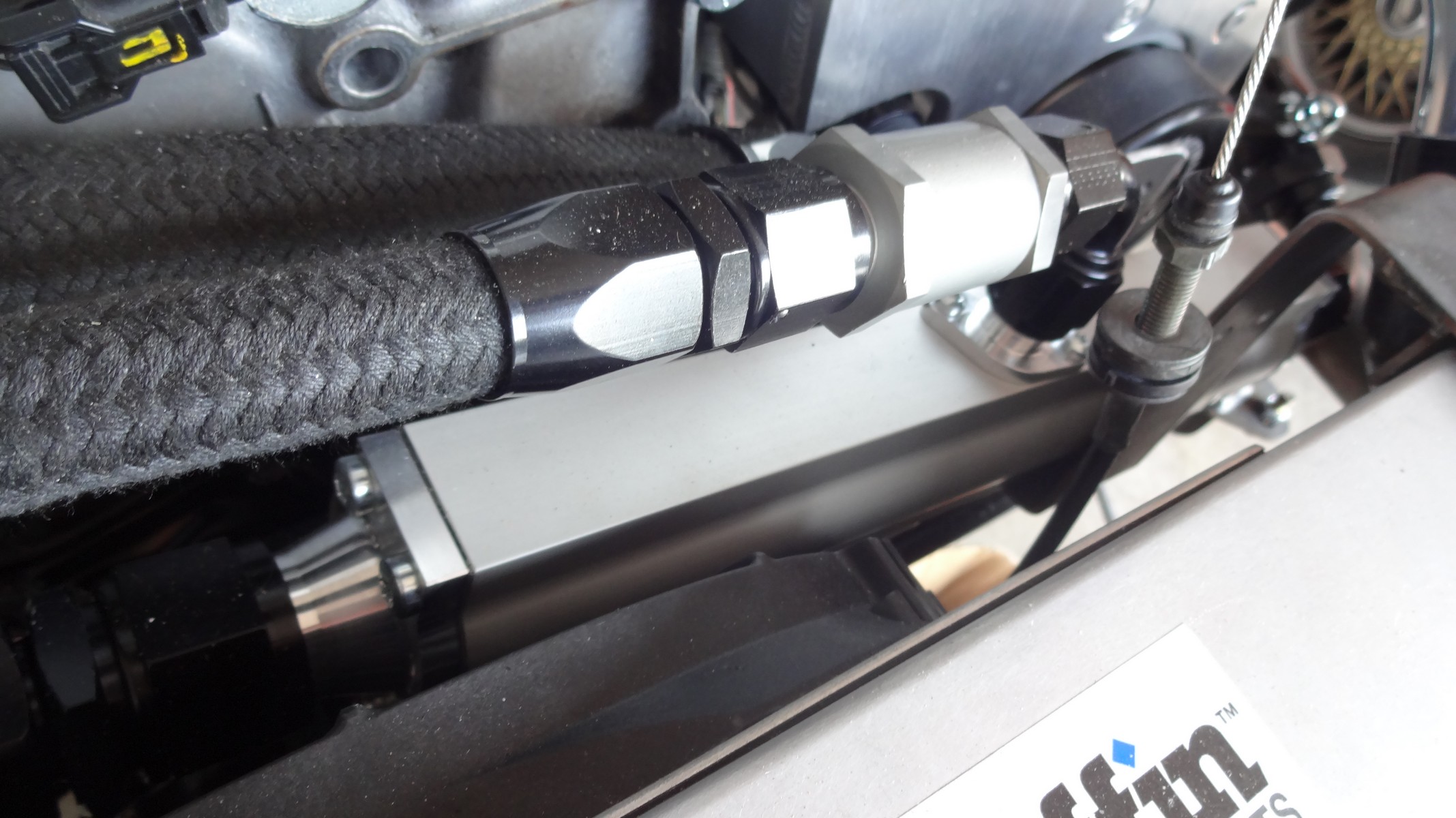

With a Laminova Oil-Coolant heat exchanger, coolant and oil transfer heat between each other. This has several benefits over a traditional oil cooling sytem. The design is compact and robust, unlike a traditional oil cooler which is more delicate, and needs to be placed in the path of airflow (and possibly rocks etc.). Additionally the Laminova does not require a thermostat, which reduces the complexity of the system. A thermostat is not needed because heat is exchanged between the oil and the engine coolant, and the coolant coming from the engine will be 190 degrees. As the exchange isn’t 100 percent efficient, this means the oil will always be at least little warmer than 190 degrees (once up to temp), which is perfect. Not only does the heat exchange process remove heat from the oil when it’s getting hot, it also adds heat to the oil when it”s cold. This warms the oil to operating temperature more much more quickly, decreasing engine warm up time.

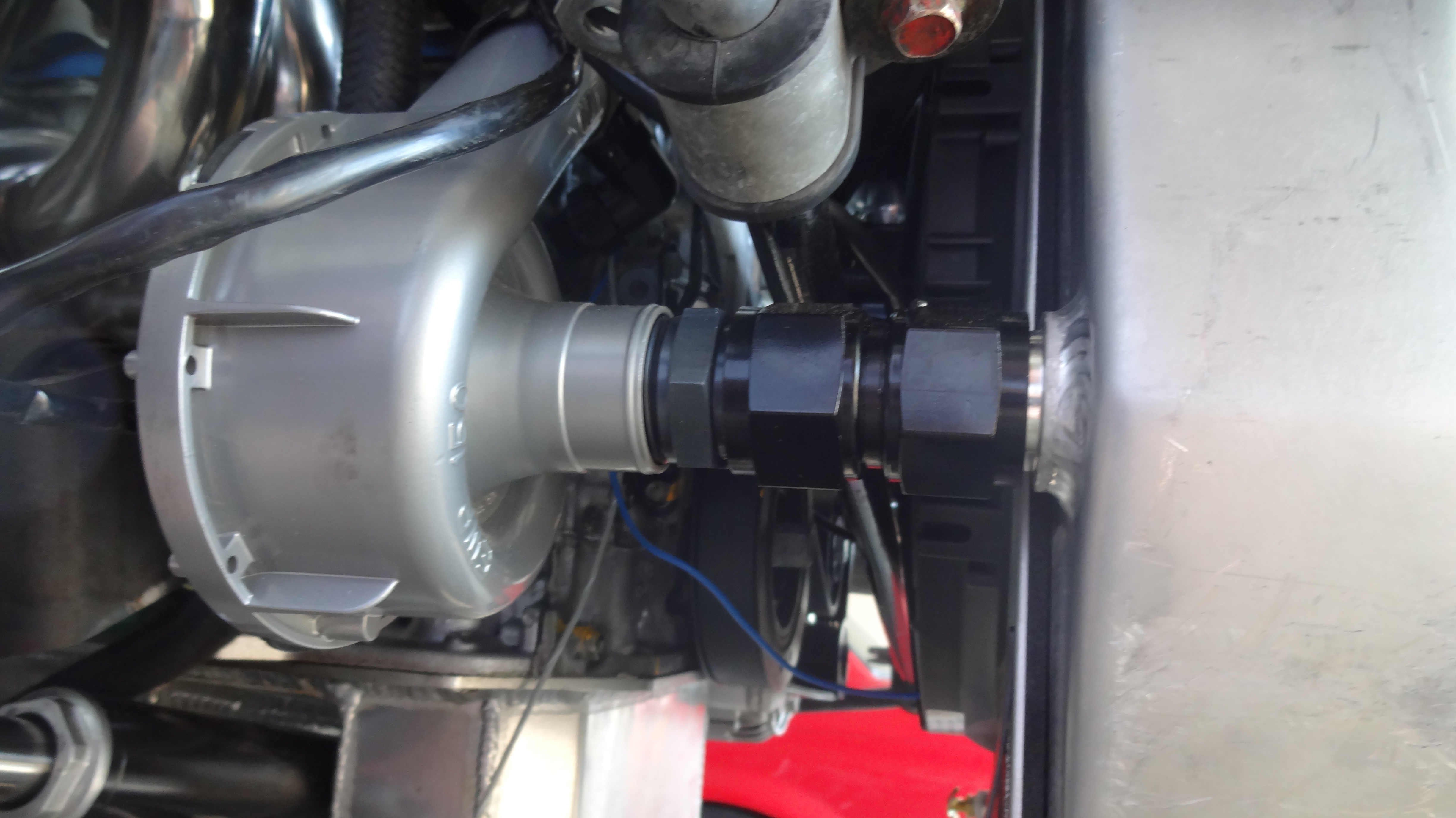

While the Laminova is relatively compact, it was still a tight squeeze, and plumbing challenge. Several different fitting and hose routing combinations were tried till a solution was found. Just like a standard oil cooler, the Laminova has to be orientated properly so the oil flow properly removes any air pockets. To help with priming after oil changes, a Peterson remote filter mount was used, which has an oil primer that is operated by a drill.

Water Cooling

The radiator is sized to allow the supercharger charge pipe to run beside it to the intercooler. There was actually an off the shelf Griffin dual pass/dual row radiator that would work for our application. It has AN fittings like the rest of the cooling system.

Electric Water Pump

In order to fit the supercharger the factory water pump had to be eliminated, which necessitated the use of an electric water pump. I chose a unit from Davies Craig, which has several advanced features:

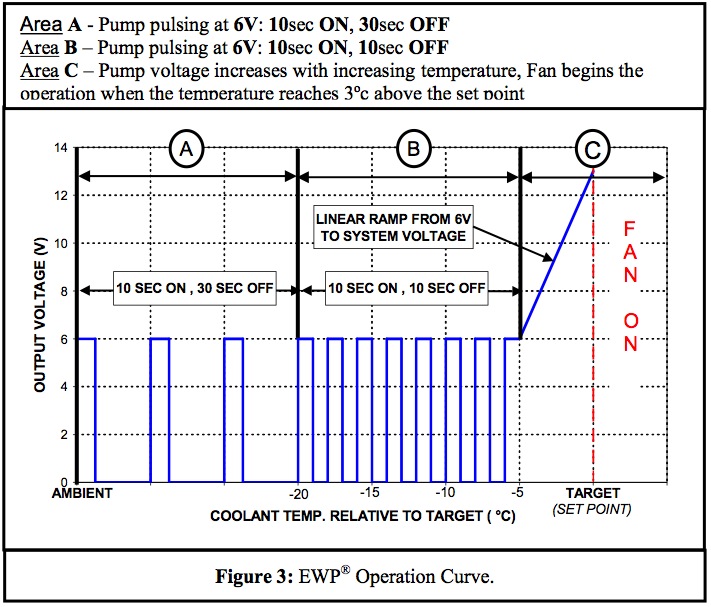

Thermostat – The engine thermostat is completely eliminated, and the running temperature is adjustable with the control unit. Instead of being “always on” like a normal mechanical or electric water pump, the control unit varies the pump’s speed. As the engine is warming up the pump will turn on and off at set intervals. As it approaches operating temperature it will ramp between 6 volts and 12 volts. Then if the operating temperature is exceeded by 5 degrees fahrenheit, such as when sitting in traffic, the controller will automatically turn on the engine cooling fan.

Heatsoak Prevention – Once the engine is shut off, the pump controller runs the pump and fan for three minutes, or until the engine temperature falls 14 degrees fahrenheit below the set operating temperature.

The pump was able to be mounted directly on to the radiator, but a support will be built for it so the pump is not placing strain on the fitting.

Cooling Fan

Cooling fans and shrouds are needed for cars that will be idling, but the shroud and fan actually hurt airflow once the car is at speed. For this reason, I made the shroud to cover only as much of the radiator as was needed to mount the fan. There will still be ample low speed cooling for an engine of this displacement, and minimizing the shroud area will improve high speed cooling. There are also rubber flaps at the bottom of the shroud that open up once the car is moving to further reduce the restriction.

Conclusion

Our implemented cooling methods should have no issue keeping our temps in check at 500hp and beyond!

Facebook Giveaway and Updates

Be sure to like our newly created facebook page to be kept up to date on the project. Simply click the button below, if the check mark appears next to the like you are good to go!

Facebook page link: https://www.facebook.com/WheelAlignmentTools/