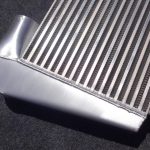

Custom Intercooler

When air is compressed by a supercharger or turbo, the process of compression increases its temperature by a significant amount. This is where an intercooler comes in. Intercoolers are placed in front of the radiator so they have access to ambient airflow. The ambient temperature air cools down the hot compressed air as it flows through the intercooler. As cooler air is denser, this enables the engine to make more power and also protects against detonation (knock).

Most cars have a nose section that is as wide as the track width of the car. Because the Exocet’s nose is much narrower, it made the packaging of a good size intercooler challenging. Additionally, because of the space constraints, unique inlets and outlets had to be fabricated. An intercooler core was purchased, leaving us the freedom to make our own end tanks for the intercooler.

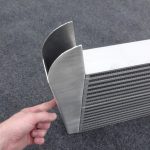

Driver Side End Tank (Intercooler Inlet)

I designed the inlet end tank to have the entrance from the backside, with the inlet tube going in between the frame and the radiator. In order to make airflow as smooth as possible, a gradual curve was formed into the end tank. This was time consuming, as the piece had to be clamped and unclamped from the bending brake many times. But somehow after all the bending the piece aligned perfectly, just a little bit extra to trim.

Next, cuts were made on both the top and bottom of the tank to taper the airflow. There is a more severe taper on the bottom because the bottom inch or so of the intercooler is not directly in line with the airflow because of the body work.

A transition piece from Burns Stainless was used (more on them later), and it was shaped into an oval to give proper clearances between the radiator and frame.

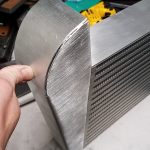

Passenger side tank (Intercooler Outlet)

For this tank, it was designed so the air would exit out the top, thus could easily be routed to the throttle body. Usually when an intercooler exits out the top, it’s through a round coupling fitting stuck onto a square intercooler tank. Not only does this create an air restriction, but it takes up a lot of space as well. With an intercooler this size, we didn’t have much space to spare because of bodywork clearance.

The solution I came up with was to have the end tank itself make the 90 degree turn, not a silicone coupler. This would save a lot of space, and if done right could be much less restrictive as well.

First, a design was sketched out on some sheet metal. Calipers were used to scribe the circular parts. Then the sheet was cut out and the angles were bent.

Next, a panel was made to cover the outer face of the curve. PVC pipe was used as a form to get a gradual angle.

Making a Square to Round Transition

Now this is the hard part. There needed to be a way to transition from a square hole to a round hole, without posing a restriction. I came up with the idea to get a round pipe, and use a vice and clamps to form it into a square. After some time searching the internet I found a company called Burns Stainless. They have all sorts of different pipe products, one of which is aluminum transitions that go from one round diameter, to another round diameter. I measured the perimeter of the square outlet of the end tank, and was able to order a transition that had a circumference matching that on one end. The other end of the transition had a 3” diameter, perfect for a 3” silicone intake coupler.

To ensure the transition bent at the right spot, little relief cuts were made in the proper places. Then using a vice and some clamps, the transition was formed into a square. After it came out of the vice there was some detail work needed to the bends, but the finished product turned out very nice.

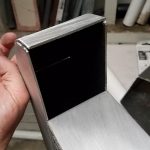

Pre-Welding

Here are some shots of all the pieces of the intercooler before they were welded.

Finished Product

Here it is after the pieces were welded up by a professional. A lot of thought and work went into it, but the result is worth it. It should provide great charge cooling, even during hot days on track.

Facebook Giveaway and Updates

Be sure to like our newly created facebook page to be kept up to date. As a bonus you will be entered in to our wheel alignment tool giveaway, all you have to do to be entered is like the page. Simply click the button below, if the check mark appears next to the like you are good to go!

Facebook page link: https://www.facebook.com/WheelAlignmentTools/